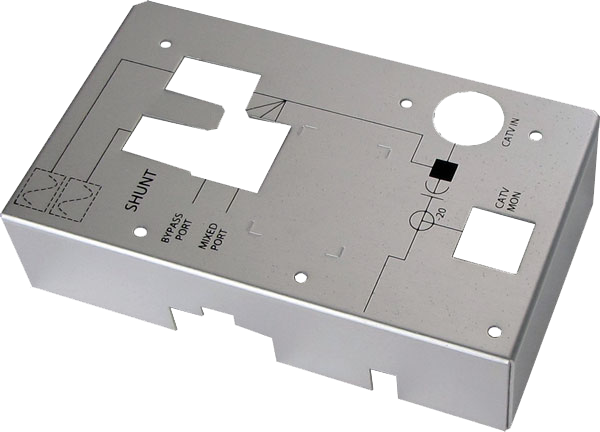

When considering a Contract Manufacturer for a Precision Sheet Metal Fabrication Process for a part to be fabricated out of sheet metal, you need to know the processes available to understand how you will design your sheet metal fabricated part to be the most economic manufactured. Each process has its positives and negatives.

Many fabricators will force-feed you what is easier for them, not necessarily what is best for your product in quality and cost. Let us summarize the primary processes; Laser Cutting, CNC Turret Punch Press, Press Brakes, and Traditional Sheet Metal Mold Stamping or Progressive Die Mold Stamping using a mold, pointing out the positives and negatives of the processes together below:

Laser cutting is a simple sheet metal fabrication process using a laser to cut a pattern out of a sheet metal sheet/plate. A sheet metal plate is put on a table, and either the laser is programmed to move, or the table is programmed to move to cut the shape required. Laser Cutting is the go-to for many products because it can be quickly and easily programmed from a 2D drawing to cut any simple to very complex shapes.

Positives:

Negatives:

Summery, if you have a low quantity, very complex shape precision sheet metal fabricated parts, stainless steel material, or thick material, Laser Cutting is an excellent option. However, laser cutting is easy to set up for the fabricator, so be aware they might force-feed you this process if they are not equipped or specialized in other processes.

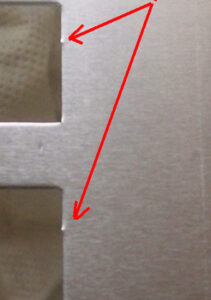

In the sheet metal fabrication process, the CNC Turret Punch Press process uses a turret that will quickly change tools to cut the desired shape, while typically, the table is programmed to move to accept the punch tool. The CNC punch tool rapidly goes up and down, and nibble’s the cutout. Think of a 2″ square hole. You would use a ½” cutter to nibble the cutout along the cut line until the cutout is complete.

Positives:

Negatives:

Summery, if you are looking at routine production parts in Carbon Steel or Aluminum between the production quantities of 100-1000 or be able to do design changes on the fly, the CNC Turret Punch Press is an excellent process to use.

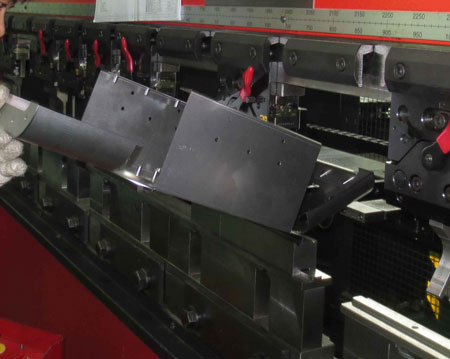

When a part is cut utilizing a CNC Turret Punch Press or sheet metal laser cutting, When a bend is required, and sheet metal press brake is used in the sheet metal fabrication process. There are typically 4 types of press brakes, fully manually Press Brake, CNC Press Brake, robotic, and automated to bend sheet metal to various bends profiles and designs.

These Press Brakes are set up to complete only one operation or bend at a time, and then the tooling is changed for the second operation. These Press Brakes are mainly used in the prototype, minimal production, or hobbyists.

CNC Sheet Metal Press Brakes take a 3D part file where the operator will input the required bends and bend angles in a sequence down the break utilizing separate preset tooling for each bend to complete a finished part. This increases the speed and accuracy of the production.

A robotic press break simply a CNC sheet Metal Press Brake replacing the human with a robot. The is another step to increase speed and accuracy of production; however, there is an increased cost in setting up for a Robotic Press Brake; therefore, an increase in quantity, MOQ, is needed depending on the number and complexity of bend is required.

This Press Brake is one system that moves the cut sheet metal part and then automatically changes the tooling and moves the part to the required position. These are used only for parts with a significant number of bends and a high MOQ.

Traditional Sheet Metal Mold Stamping is a sheet metal fabrication process requiring a mold to replicate the parts. For small, simple parts, a single mold can cut and bend the sheet metal without the need for a press brake. Depending on the exact Traditional Sheet Metal Mold Stamping process, you can punch martial of copper, nickel, aluminum, steel, and stainless steel to great thicknesses.

A “progressive die stamping” mold can be used to increase efficiency over multiple molds. A progressive die is a single mold where a long strip of material from a coil is fed into one end as it goes through the mold from one end. The material is punched in steps. As it is pushed through the mold at the far end/exit, the final step cuts the material off, and a finished part is dropped off. In Traditional Sheet Metal Mold Stamping, for larger and more complex the part becomes, 2+ molds are used.

Positives:

Negatives:

Summery, if you have a high production quantity sheet metal fabrication with a long-life cycle that allows you to amortize the mold cost, this is the process of choice.

Other areas in the sheet metal fabrication process you should consider when at your design stage but not limited to are:

The sheet metal fabrication process comes down to cost depending on your product and quantity. Think of a 2″ x2″ x2″ open-ended box out of 16 Gauge aluminum to understand more clearly. Laser Cutting and Press Brake bend would take less than 2 minutes to produce. On the other hand, a CNC Turret Punch Press and Press Brake Bend would take less than 1 minute to make. Last, a Traditional Sheet Metal Mold Stamping would take less than seconds to produce.

For the sheet metal fabrication process, you must consider the last two items, a “Cradle to Grave” and a FULL-SERVICE COMPONENT CONTRACT MANUFACTURER.

FULL-SERVICE means the contract manufacturer can provide you with a finished part including machining, PEM/Fastener installation, Powder Coating, Plating (anodizing, Chromate, Alodine, and so on) &silk screening/engraving, a “one-stop-shop” This eliminates having to resend out your part for a secondary process to separate multiple vendors. The significant advantage of this is you now only have one source responsible for your quality and on-time delivery needs.

“Cradle to Grave“ means as your product matures, we will continually give you suggestions (process changes, material changes, sub-assemblies) to reduce your cost giving you an improved sales advantage. Ionthis can do both!

For a DFM/Analysis of your Sheet Metal Fabricated component or assembly, feel free to contact Ionthis at engr@ionthis.com.