Home » Plastic Product Manufacturing Process

In the world of plastic product manufacturing, many different processes make it confusing which process is the best process for your unique product. This page will explain some of the most used processes, the material used in each, and each’s strengths and limitations. These will allow you to select the process that meets your unique MOQ, Engineering/Design, manufacturing, and COST requirements. The plastic manufacturing processes we will discuss are:

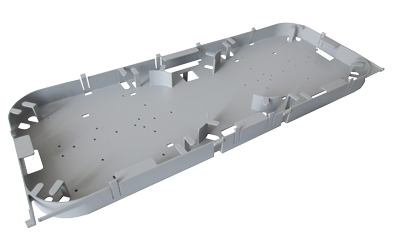

When machining plastic in Plastic Product Manufacturing is relatively endless machining process possibilities to machine plastics as long as the plastic is rigid, most thermoplastic plastic with a few thermosetting plastics can be machined.

Any standard machining process can be used. Machining is one of the most underutilized processes since 3D printing became readily available. It is common to think that a prototype utilizing 3D printing is the lowest cost. Printing might be true for smaller parts, one, two, or five parts. However, more significant, more complex parts with runs from 3-25 machining can be the more economical and quicker

Machining can be economical for quantities of 1-25 in 1-3 weeks

Parts will have machining marks and are better suited for machine shops specializing in machining plastics with powder coating to give the part a more cosmetically pleasing look. Some plastic injection molding factories specialize in this type of machining.

They are relatively endless as long as they are rigid, mainly in thermoplastic plastic with a few thermosetting plastics that can be machined.

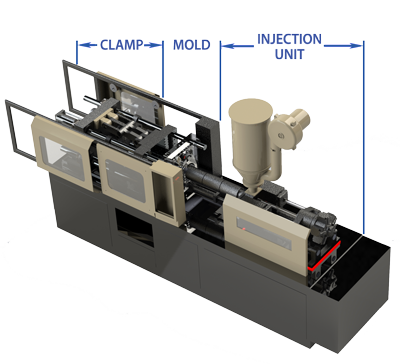

Plastic injection molding uses “thermoplastics,” plastics that melt with heat and inject the melted plastic into a mold cavity to create a cavity image, the finished plastic part. A typical plastic injection unit can be broken out and explained in three specific areas

A. The Thermoplastic Injection Unit

B. The Mold

C. The Clamp

The Plastic Injection molding Unit is comprised of 5 major parts:

The injected molded plastic pellets are first put into the hopper in the plastic injection molding process, which feeds the Injected molded plastic pellets into the plastic injection unit’s barrel. As the reciprocating screw turns, the pellets are pushed forward and mixed by the injected molded plastic screw’s flutes/flights on the screw. The plastic injection molding screw diameter increases closer to the mold. The combination of the friction of the screw action and heat distributed by the heating bands, the injected molded plastic melts, and it is fed into the chamber in front of the screw.

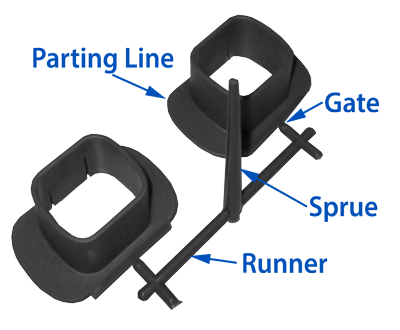

Then the hydraulic ram pushed the screw forward, injecting the mold sprue with the melted injected molded plastic in a matter of seconds. Most times, in less than seconds, the injected molded plastic component is ejected out of the mold, and the plastic injection molding process repeats itself. For larger plastic components and plastic housings, the timing will be longer.

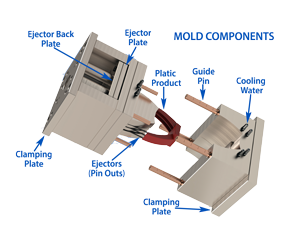

The Plastic Injection Mold is comprised of

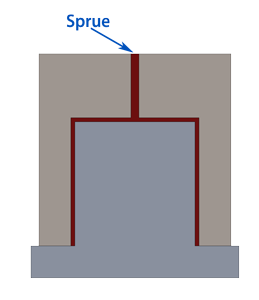

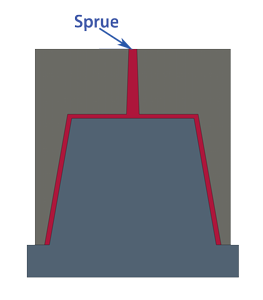

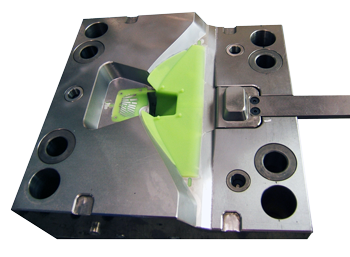

The Thermoplastic Mold Process in Plastic Product Manufacturing: The plastic injection molding process starts when the Injection Unit injects the melted thermoplastic into the sprue. This inlet feeds the thermoplastic into the mold cavity in a closed plastic mold. Cooling water is circulated in the mold through water channels to help speed up the Thermoplastic solidification. Once solidified, the mold will only slightly open a 1/64″-1/32 to break the vacuum for a couple of seconds the open all the way.

The ejector plate and backplate move forward, pushing the ejector pins, which forced the finished plastic injection molding part and ejected it from the mold cavity. The ejector assembly moves back, the mold is closed, and the operation repeats itself in plastic injection molding.

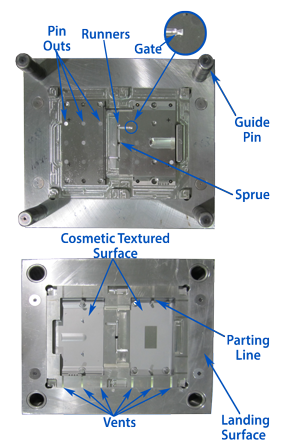

Mold Design: When designing a part and having a plastic injection molding designed and manufactured to produce your part out of injected molded plastic, you need to have a more detailed understanding of design and mold components considerations to:

These considerations are (see the Mold Diagram) for injected molded plastic:

The clamp houses the mold in the thermoplastic injection unit for plastic injection molding. Before the injection process, the two halves of the mold must be mounted to the “clamp.” On either side of the clamp, there is a large stationary plate called the platen. Each side of the mold must be mounted to the corresponding platen. The front half of the mold, the mold cavity, is mounted to the front plate aligning with the plastic injection molding unit nozzle. The rear plate, the core half of the mold, is mounted to the rear platen that operates, moves the mold utilizing a large hydraulic ram for the injected molded plastic.

Thermoplastics in plastic injection molding come in injected molded plastic pellets that can be mixed to get the desired color or transparency:

Although the processes vary slightly between the LSR injection machines’ manufacturers, typically, the LSR (Liquid Silicon Rubber) Injection Molding starts with two buckets are barrels of different silicone components in plastic product manufacturing. These components are then pumped into a mixer. The mixed material is COLD. The LSR is then sent to a screw. Sometimes the screw will directly inject the LSR into the mold or send the mixed LSR to a separate plunger that injects the mixed LSR into a HOT (275F-390F) mold that rapidly solidifies the LSR part, and then the part is removed.

Rubber/Silicone Compression Molding: This is one of the oldest simple molding processes in plastic product manufacturing. Rubber/Silicone Compression Molding only has two major components:

A. The Mold

B. Compression Press

The compression molding process is also relatively simple. A premeasured amount of un-vulcanized rubber or silicone material, slug, is placed in one half or both halves of the mold. The mold is closed and heated to a predetermined time, and the rubber or silicone is vulcanized.

First, when you first select the correct plastic product manufacturing process, it comes down: what material you require, the NRE cost you can recuperate, and the physical geometry of the part to be manufactured.

Second, the last two items you must consider for plastic product manufacturing are a “Cradle to Grave” and a FULL-SERVICE COMPONENT CONTRACT MANUFACTURER.

FULL-SERVICE means the contract manufacturer can provide you with a finished cast part including machining, PEM/Fastener installation, silk screening/engraving, and metal components if required, a “one-stop-shop“eliminating having to resend out your part for a secondary process to separate multiple vendors. This makes controlling processes errors from various sources difficult.

“Cradle to Grave” means as your plastic product manufacturing matures, we will continually give you suggestions (process changes, material changes, sub-assemblies) to reduce your cost giving you an improved sales advantage. An example would be at the beginning of marketing your product, PROTOTYPING. Your volumes are low, and you do not want to invest in molds and manufacturing quantity; Ionthis could make your finished part parts by machining from a solid block or unitizing an aluminum mold.

Your NRE investment would be low, but the part price might be higher but absorbable. When your volume gets high enough to justify the NRE, Ionthis can move you into high-production molds. This is “Cradle to Grave.”

For a DFM/Analysis and recommendations of your Die-Cast, Investment Cast, and Sand Cast component or assembly, feel free to contact Ionthis at engr@ionthis.com.