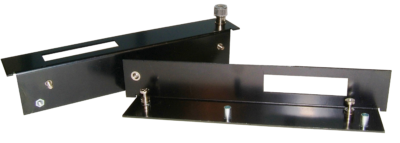

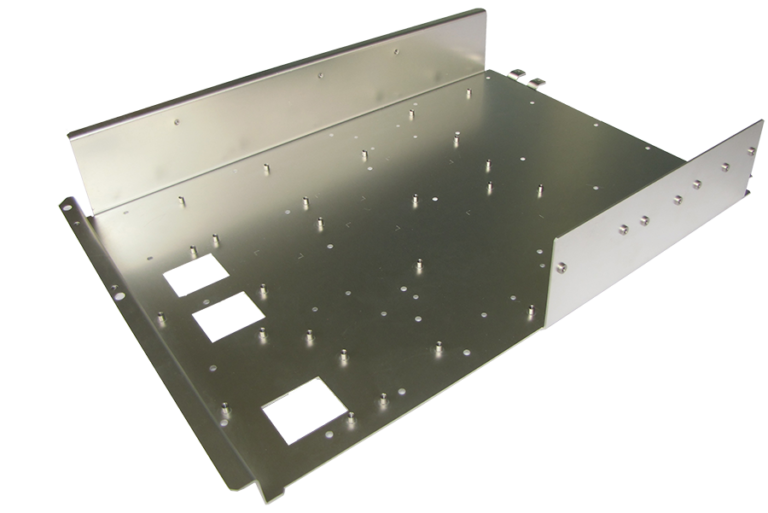

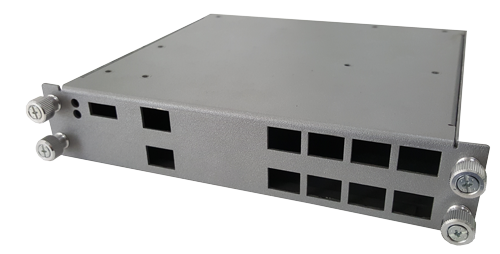

Ionthis manufactures custom Sheet Metal Chassis, Housings, Bracket Assemblies, and various Components. Our sheet metal capabilities include types of sheet metal fabrication; CNC Turret Punch Press, Traditional Sheet Metal Mold Stamping, Progressive Die Punch Press, Press Brakes, Laser Cutting. A complete list of our Sheet Metal Fabrication Capabilities is listed below, including our full-service options.

What makes Ionthis a unique Precision Sheet Metal Fabricator is that we can offer our customers choices on sheet metal fabrication services and different process options to best suit their design, production, market, and cost. Requirements include a CNC Turret Punch Press / Press Brake versus a Progressive Die Punch Press. This allows our customer to make their best-informed decision and not force-feed them in only one process. To understand the differences in each process and sheet metal fabrication techniques plus the positives and negatives, please see our section “Sheet Metal Fabrication Process” under MFG Processes explain

When looking at a sheet metal fabricator’s capabilities, customers are primarily concerned about the lowest cost at a specific MOQ (Minimum Order Quantity). As explained in the “Sheet Metal Fabrication Process,” if you used a CNC Turret Punch Press or Laser Cutting to cut the design profile, you must use a Press Brake to do the bending.

In production manufacturing, there are three types of Press Brakes that are used:

Standard Mold Sheet Metal Punch Press will do the cutting and bending in 1 to several molds, whereas a Progressive Die Punch Press will do all the cutting and bending in a single mold. Below we show Ionthis’s capabilities with the addition of the cutting and braking process and the MOQs typically expected.

The MOQs are driven by the complexity of the design, size of the design, material type, and material thickness. An example of the differences is if you have a large 12 gauge Aluminum Enclosure at an MOQ of 100, the CNC Turret Punch Press /CNC Press Brake is the best choice. However, if you have a large eight gauge Stainless Steel Enclosure at an MOQ of 100, the Laser Cutting/CNC Press Brake would be the best option.

In the sheet metal fabrication process, as the parts’ MOQ quantity increases beyond CNC Punch Press or Laser Cutting and Press Brakes, production capacity plus a demand for the unit part cost decreases. It is time to start looking at Traditional Sheet Metal Mold Stamping or Progressive Die Stamping that does the work of both the CNC Turret Punch Press and the Press Brake.

In this case, the customer must be willing to amortize the Traditional Sheet Metal Mold Stamping or Progressive Die Stamping NRE cost over its life/number of parts to mold failure and reduce the production time of using a separate CNC turret punch press and a press brake. There are two types of molds, as explained in “Sheet Metal Fabrication Processes,” and they are:

The selection between the 2 is primarily MOQ driven. The Traditional Sheet Metal Mold Stamping typically uses 1-3 separate molds to cut, punch, and bend the part producing quantities from 500 to 100K+.

The Progressive Die Stamping is a single mold that feeds the metal from one end to the other, progressively cutting, punching, and bending the parts as it goes through the mold until the part is finished on the other side. Quantities can range from 10,000 to 1M+; however, the mold cost is 2-10 times the cost.

FULL-SERVICE means the contract manufacturer can provide you with a finished part such as powder coating, silk screening, and fastener installation. Ionthis is a “one-stop-shop. “ This eliminates having to resend out your part for a secondary process to separate multiple vendors. The significant advantage of this is you now only have one source responsible for your quality and on-time delivery needs. Below are our typical but not limited to capabilities:

“Cradle to Grave” means as your product matures, we will continually give you suggestions (process changes, material changes, sub-assemblies) to reduce your cost giving you an improved sales advantage. An example would be perhaps at the beginning of marketing your product, your volumes are low, and you do not want to invest a Traditional Sheet Metal Mold Stamping; we would start by using a CNC Turret Punch Press and Press Brake.

What Ionthis could make your finished part from CNC Turret Punch Press or Laser Cutting and bending with a CNC Press Brake and the beginning with little or no NRE investment. When your volume gets high enough to justify mold for Traditional Sheet Metal Mold Stamping, Ionthis will recommend moving you into a mold or even evolving to a cast or plastic part or assembly. This is “Cradle to Grave.”

For a DFM/Analysis and recommendations of your Precision Sheet Metal Fabrication component or assembly or any sheet metal fabrication projects, feel free to contact Ionthis at engr@ionthis.com