Home » Die & Investment Cast

Home » Die & Investment Cast

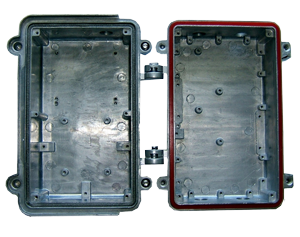

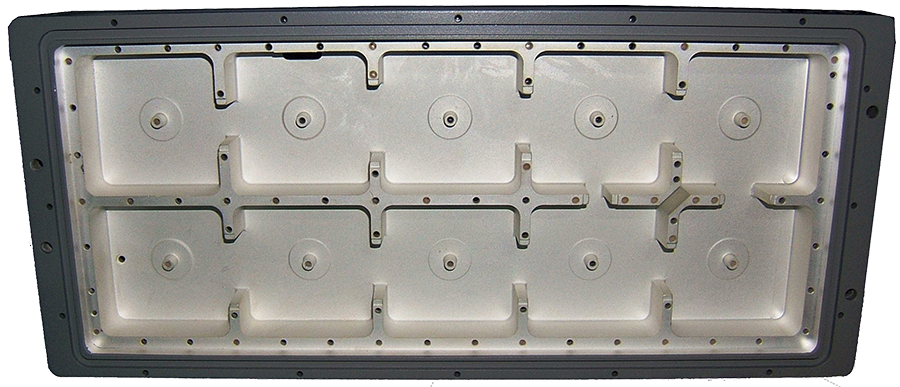

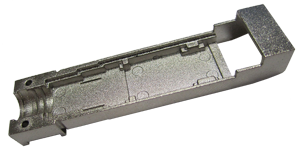

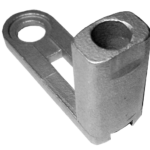

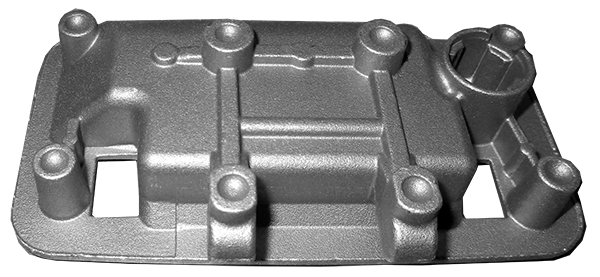

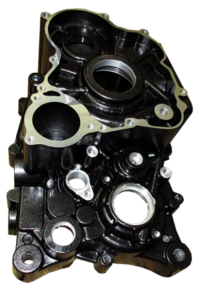

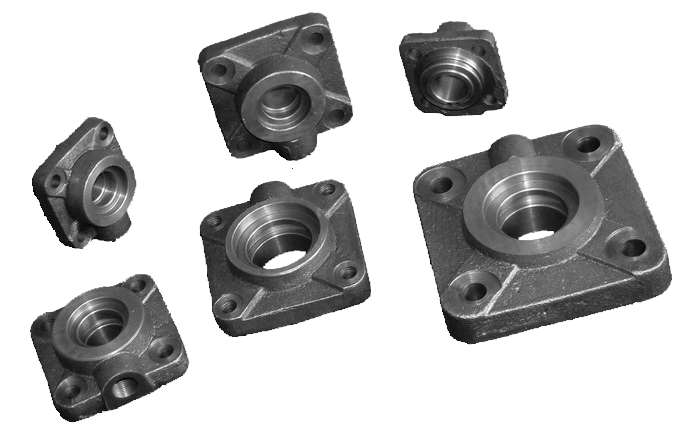

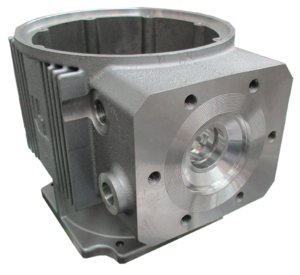

Ionthis manufactures custom Die-Cast, Enclosures, Housings, and Components, Investment Cast Housing, End Caps, Brackets and Components & Sand Cast Brackets, Enclosures, Motor and Pump Components and Valve Components, and more. Our contract manufacturing Casting Capabilities include Automatic /Robotic and Manual Cast with Individual Crucible Furnaces allowing for small to large production runs.

Ionthis strengths include die-cast per standards, investment cast, and sand cast designs that can be tailored/engineered to our customers’ casting needs. Since we offer several casting processes, our engineering will review our customers’ design requirements and present options on which casting process meets the design requirements and will provide the best cost and quality. Please see our section “Die, Investment & Cast Process” under MFG Processes explained to understand each process’s differences and the positives and negatives.

If our customers are looking at castings as an option for their component, they must consider the MOQ, NRE (Mold Cost), material, and possible machining after casting. Each casting process has positives and negatives for each of these.

FULL-SERVICE means the contract manufacturer can provide you with a finished part such as machining, powder coating, silk screening, Plating, and fastener installation. Ionthis is a “one-stop-shop“. This eliminating having to resend out your part for a secondary process to separate multiple vendors. The significant advantage of this is you now only have one source responsible for your quality and on-time delivery needs. Below are our typical but not limited to capabilities

“Cradle to Grave” means as your product matures, we will continually give you suggestions, (process changes, material changes, sub-assemblies) to reduce your cost giving you an improved sales advantage. An example would be perhaps at the beginning of marketing your product, your volumes are low, and you do not want to make the investment in die-cast molds and tooling and manufacturing a large quantity,

Ionthis could make your finished prototype part(s) from sand cast or even economically machine the part from a solid metal block. Your NRE investment would be low but the part price might be higher but absorb-able. When your volume gets high enough to justify die-cast Ionthis can move you into a Die Cast. This is “Cradle to Grave”.

For a DFM/Analysis and recommendations of your Die-Cast, Investment Cast, and Sand Cast component or assembly, feel free to contact Ionthis at engr@ionthis.com