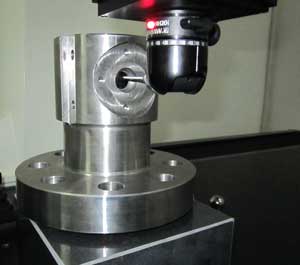

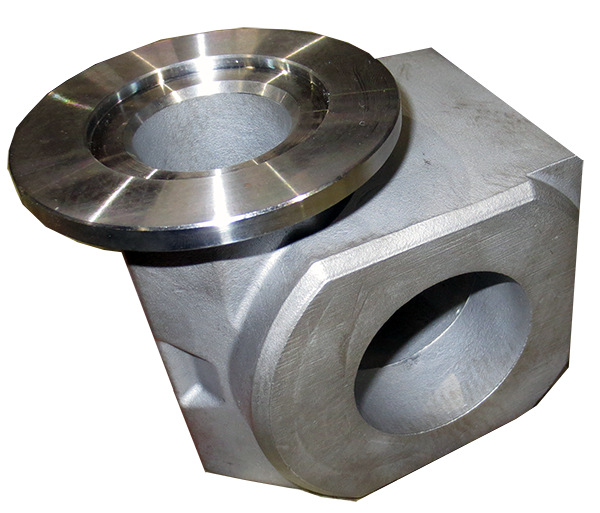

Ionthis has Custom Machining & Forging capabilities that far exceed our competition. What makes Ionthis unique is our engineering and technical team will take your product and design, quality, and YOUR quantity needs and match them with the correct or possibly a couple of processes to meet our customer needs. This allows you to make their best-informed decision and not force-feed them only one process. If required, we will produce a “near finish forging or casting to meet your requirements further. Please see our section “Machining & Forging” under MFG Processes explained to understand each process’s differences and the positives and negatives.