Home » MFG Process Blog » Applications of Sheet Metal Fabrication

Applications of Sheet Metal Fabrication

Since the sheet metal fabrication industry is projected to reach $4.4 billion by the end of 2026, it’s clear that this process has new applications that are being discovered each day.

Suppose you are considering custom fabricated sheet metal. In that case, you are likely wondering what some of the most significant applications are so that you can see whether or not sheet metal fabrication over plastic, casting, or extrusion is suitable for your needs. Read on to learn some basic custom sheet metal fabrication applications and get more insight into how sheet metal fabrication can be best used in the electronics industry.

Table of Contents

Basic Applications

There is a multitude of industries across the world that use sheet metal fabrication in their daily operations. These industries include electronics, telecommunications, lighting, construction, automotive, aerospace, and energy.

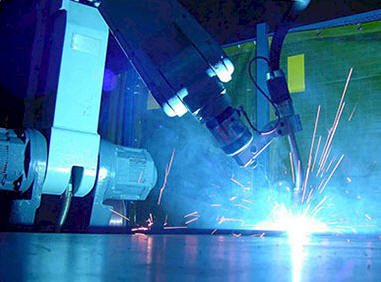

Fabricated sheet metal is common and critical in these markets. It builds various structures such as sheet meat chassis, enclosures, housings, cabinets, brackets, and other components from raw sheet metal materials. The machinated cutting, burning, laser cutting, and welding processes are perfect for creating sturdy structures such as cranes/other assembly tools in construction, auto parts, airplanes, and windmills/solar panels.

As the industry grows, so do the technologies used to produce fabricated sheet metal. In 2021, there will be significantly more CNC/robotics machine automation than there previously has been, so machine operators can simply follow instructions from an uploaded file to cut and form sheet metal faster than ever before. Traditional sheet metal punch press technologies have also advanced with automation and robotics. Additionally, ERP systems and 3D printing are increasing in these industries.

The end result of these changes is that fabricated sheet metal is more accessible and economical than ever before. Therefore, the applications for its use are growing each day.

Sheet Metal Fabrication in Electronics

The majority of applications for sheet metal fabrication are in the electronics industry. This makes sense when you consider that it is worth nearly $839 billion and is incredibly diverse in its offerings. Cell phones, drones, computers, tablets, telecommunications communications equipment, audiovisual equipment, LED lighting, automated machinery used in factories, and automatic household appliances all fall into the ‘electronics’ category.

Sheet metal fabrication is used when prototyping essentially almost all electronic enclosure and component parts. It is an inexpensive process using CNC sheet metal turret punch presses, laser cutting, water jet cutting, and press brakes and is incredibly quick, which means that you can view and examine your prototype at a low price. If you need to make any adjustments, this can be performed quickly and efficiently. This will allow your electronic enclosure or component part to go to market ASAP utilizing the CNC sheet metal turret punch presses, laser cutting, water jet cutting, and press brakes for smaller quantities or Traditional sheet metal punch presses for a larger production.

Chassis Construction

Even though sheet metal fabrication can be low cost and quick when you need it to be, it can also be a more involved process that produces durable parts. The end-use metal part can be made with a wide variety of materials that use durable coatings and finishes that meet your specifications.

Prototyping sheet metal is often simple and low-cost aluminum. However, more durable prototyped parts can be made with stainless steel, copper, nickel, and other alloys prototyping using a CNC sheet metal turret punch press and press brake. It is an extremely versatile technology.

Because you can take sheet metal and weld it into hard, durable, and long-lasting components, you can construct chassis easily. These structural frameworks are essential to a wide variety of equipment, including audio technologies, drones, and passenger cars. Frames must be sturdy enough to support the rest of the technology’s weight, which makes the durable machination methods used in sheet metal fabrication a great choice.

Enclosers and Housings

Suppose you need a protective shell to enclose your electronic mechanism. In that case, sheet metal fabrication is a simple and durable alternative for small to medium-sized sheet metal enclosures to large sheet metal cabinets over panel benders and folding machines.

Sheet metal fabrication allows economical enclosures and housing to protect gearboxes and other sensitive electrical equipment effectively and serve as a barrier between the mechanism and the elements from the outside world. It stops outside debris from getting in and can be manufactured as a waterproof solution such as NEMA 6, NEMA 6P, IP67, or IP68 sheet metal enclosure. CNC or robotically welded metal does not have any openings or gaskets, or O-rings can be used at seams through which water, fuel, or dust can enter into the mechanism.

Because sheet metal fabrication allows for custom-designed results, you can also create user interfaces on your housing. Areas can be ergonomically designed for buttons that users can press down on, which is useful for applications such as remote-controlled construction machines, video game controllers, and computer sheet metal housings. Additionally, a multitude of cutouts can be manufactured for cable connectors like HDMI or CAT8, fan installation, glass windows, Light Pipe, Switches, and LED panels.

Brackets and Small Components

Sheet metal can be fabricated to create small parts such as brackets or cable connectors. Steel, stainless steel, aluminum, and copper alloys are sturdy enough to hold larger metal or plastic pieces together without breaking. Assuming that you use corrosion-resistant metals like stainless steel sheet metal or plated/coated components, they will not be susceptible to water or corrosion damage.

This is essential for those constructing electronic equipment such as computers and audio equipment, which get a tremendous amount of use and therefore have many opportunities to be broken. Spills and debris ingress are to be expected when it comes to laptops, work computers, and mobile devices. It also is essential for electronics intended for outdoor use, such as telecommunications and security equipment, LED floodlighting or factory machinery. Sheet metal fabrications are ideal for making sheet metal chassis, and other assemblies made NEMA 6p or IP68 waterproof.

In conjunction with 3D printing technologies, sheet metal fabrication can also make small components that constitute electronic devices’ inner workings. Gears, components for hard drives and motherboards, and more can be made from durable fabricated metals very quickly using a CNC sheet metal turret punch press and press brake.

Get Started

Regardless of the industry, you are using fabricated sheet metal for, you will want to invest in a full-service process for creating your products. Our professionals offer full-service contract manufacturing along with powder coating, plating, fasteners, welding, silk-screening, and more

Now that you know some key applications for sheet metal fabrication and understand how our full-service process can meet your needs, it’s time to get started. Contact Ionthis with any remaining questions that you may have about sheet metal fabrication tools, processes, and benefits.

We service a multitude of clients in the electronics industry as well as those who need custom sheet metal for other applications. Regardless of your needs, we look forward to hearing from you soon.

It’s interesting to know that aluminum fabrication can be very useful in the field of electronics. I’m interested in learning more about tinkering with electronics at home because I’ve always been interested in building my own mechanisms on my own. Perhaps hiring aluminum fabrication services will help me in acquiring custom housings for my creations.

This is ionthis best blogging and Because sheet metal fabrication allows for custom-designed results, you can also create user interfaces on your housing. Areas can be ergonomically designed for buttons that users can press down on, which is useful for applications such as remote-controlled construction machines, video game controllers

Washpod Consolidated is Australian owned and operated Australia’s LeadingAqueous High Impact Parts Washer, Washpod is offering the best industrial parts cleaner in Western Australia or you can hire the parts washer in Western Australia.

https://washpod.com.au/

It’s interesting to know how sheet metal fabrication is can be custom made into specific brackets and connectors and they are incorporated with other metal elements for stability and durability. I would understand how certain inventors need to have specific parts made. This is probably where services come in to make these specific components.