Home » MFG Process Blog » 7 Benefits of Using Investment Casting in Manufacturing

7 Benefits of Using Investment Casting in Manufacturing

When you think of the ancient Egyptians, you probably think of the pyramids. Well, they did more than building a famous world wonder.

Thousands of years ago, the Egyptians used investment casting to manufacture goods, and people still use that process today.

It may have a long history, but investment casting works well for manufacturing a variety of products. Keep reading to learn the basics and benefits.

What Is Investment Casting?

Investment casting uses a wax pattern and a refractory ceramic material. The ceramic material covers the wax, and as the ceramic hardens, it will form a shape of the wax parts, forming the mold.

Then, you put the mold into a furnace to melt the wax out of the inside and harden the ceramic on the outside, and you replace it with molten metal. Next, you wait until the metal cools and solidifies.

Finally, you break off the ceramic exterior and finish with the metal casting.

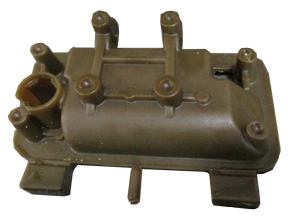

You can use investment casting to manufacture thin and complex parts. You will end up with a good surface finish, and there will be high dimensional accuracy.

Also, you can use investment casting for manufacturing a variety of metals.

Benefits of Investment Casting

When selecting a manufacturing process, you should consider its benefits. Luckily, investment casting offers plenty of advantages for manufacturers.

You can use it for many manufactured components, and it is relatively easy. Whether you want to work with a contract manufacturer or produce the items yourself, investment casting could be the right option for your products.

Whether you are new to manufacturing or are looking to reevaluate your process, consider these benefits of investment casting

1. Smooth Finishes

The first benefit of using invest casting is that you will get a smooth finish. When working with metal, the last thing you want is to have rough edges.

The wax pattern is made in an injection mold, so you will have minimal parting lines that are easy to remove off the wax pattern if you request. So, you won will not have any parting lines, so you do not have to worry about removing them from the casted metal part.

Whatever you want to manufacture, you should aim for a smooth finish. If you are considering machined investment casting, you do not have to worry about having to smooth out the edges.

In many applications, you can use investment casting “as cast” with no secondary processes. However, you can still glass bead or polish the outside of your finished investment cast. Then, you can make sure there are not any visible issues.

2. Help from Wax

Another name for investment casting is lost-wax casting. It has been used for thousands of years, so it has a long history.

Investment casting is relatively easy since you start with a wax mold. You can shape the wax how you want, and you will use that to form the ceramic shell.

As you work with the wax, you can get a good sense of how your manufacturing will look at the end. You can then melt out the wax and pour in the metal, and you will not have to worry about the shape or size of the product.

3. No Machining, Welding or Assembly Required

While some manufacturing methods require complex processes, investment casting is a little different. In many cases, investment casting can be used “as cast” and does not normally require any machining, welding, or assembly.

You can create a mold of whatever you need to manufacture, and the mold lets you create it in one piece.

The process can save you time since you will not have to weld pieces together. Creating a single piece also saves you from having to assemble the item otherwise.

If you want a simple manufacturing process, investment waxing is a good option.

4. Good for Manufacturing Complex Parts

Because investment casting simplifies the manufacturing process, it is great for complex parts. It works well whether the thickness of the walls is small or large.

You can use it to manufacture anything that you can create a wax mold of.

However, it is not the best option for items that weigh more than fifty pounds. If you manufacture larger items, you may want to consider sand-cast, die-cast, fabrication, or other manufacturing methods.

Still, you do not have to manufacture simple products to benefit from investment casting. You also do not have to be a manufacturing expert in using a wax mold or following the casting steps.

5. Works with Different Metals

Whether you work with aluminum, stainless steel, or another metal, you can use investment casting. It works well with a variety of metals, including:

- Nickel

- Silver

- Brass

- Carbon Steel

- Copper

Because of this, you have more control over the materials and design of your products. If you want to use investment casting, you do not have to compromise on the design or metal you use.

Instead, you can choose the metal and design that you need for your product. Having that flexibility can be nice, whether you are new to manufacturing or looking to change your process.

6. Works in Many Industries

Since investment casting works well with different metals, another benefit is that you can use it for different industries. You can use investment casting to create components of different types.

Whether you produce stainless steel parts or aluminum plates, you can use low-wax casting.

You can use a current product of yours to replicate with the wax mold. Or you can create a new mold.

The flexibility offers means that you can use it for almost any metal item you need to manufacture.

7. Low-Volume Requirements

Another fantastic benefit of investment casting is that you do not have to manufacture a large quantity. You can create as few as 100 or as many as 5,000 products while following normal cost efficiency.

If you are testing out a new product or a specialized one, you do not have to worry about manufacturing a ton only to waste a lot of them.

And if you do not need the most cost-efficient process, you could manufacture even fewer than 100 units. Still, 100 is not a lot, so you can choose the number of units that works best for your product.

Whether you are manufacturing your first product or your fifth, starting with a low volume means you can experiment. You can see if people want the product, and you can make any changes without wasting a ton of units.

Manufacturing Made Simple

If you need to manufacture products for your business, you should choose the best method. Investment casting has a lot of benefits, from having a smooth finish to working for various materials.

You do not have to have a ton of money to start, so it is also great for creating a few units.

Are you ready to start investment casting? Contact us to learn more about how we can help.

Like!! I blog frequently and I really thank you for your content. The article has truly peaked my interest.

This is ionthis best blogging and You can use it for many manufactured components, and it is relatively easy. Whether you want to work with a contract manufacturer or produce the items yourself, investment casting could be the right option for your products Washpod Consolidated is Australian owned and operated Australia’s LeadingAqueous High Impact Parts Washer, Washpod is offering the best industrial parts cleaner in Western Australia or you can hire the parts washer in Western Australia.

https://washpod.com.au/