Home » Extrusions and Heat Sinks

Home » Extrusions and Heat Sinks

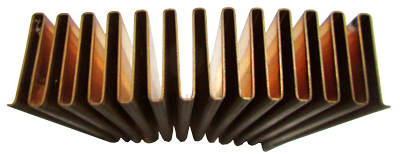

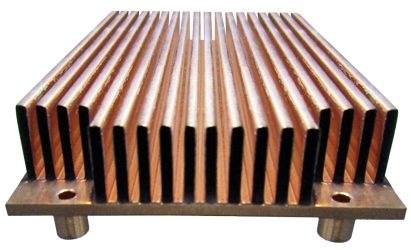

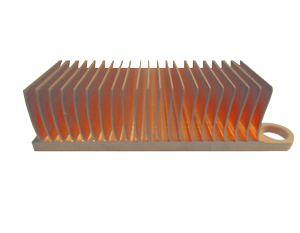

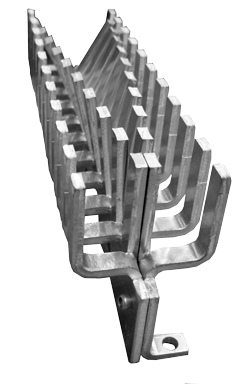

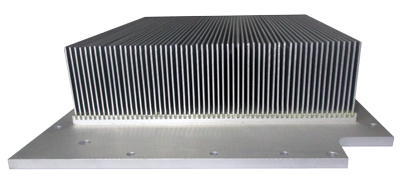

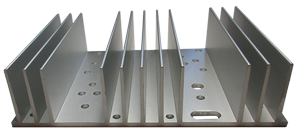

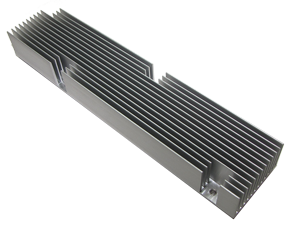

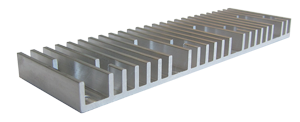

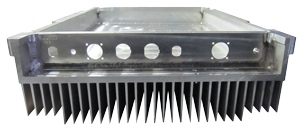

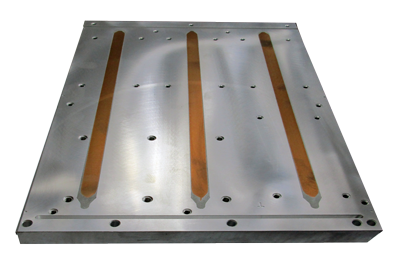

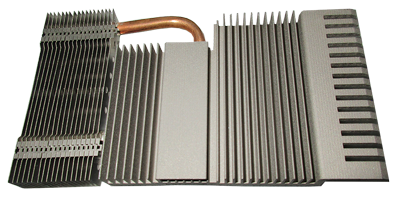

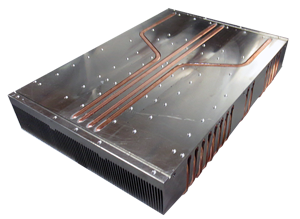

Ionthis manufactures Extruded Aluminum Heatsink, Aluminum Extrusions, and Heat Sinks, and Heat Pipes, including Aluminum Extruded Enclosures, Housing and components, and multitudes of Mechanical Heat Dissipating Components, including: :

We specialize in finished components. We are capable of extruding the smallest cross-sections up to 30″. This means we only extrude the material that meets the quantity requirements, not force-feed our customers’ hundreds of feet they cannot use.

We also finish the part including Machining, Welding, Anodizing, Plating, Powder Coating, Silk Screen, and much more, as shown below. By providing full service, contract manufacturing, our customers’ complete control of their quality from a single source. For more information about the Extrusion Process and more details on the other heat sinks above, please see our section “Extrusion and Heat Sink Process” under MFG Processes explained.

Ionthis is a “Cradle to Grave” and a FULL-SERVICE COMPONENT CONTRACT MANUFACTURER.

FULL-SERVICE means the contract manufacturer can provide you with finished extrusions and heat sinks, including but not limited to:

We are a “one-stop-shop “ for extrusions and heat sinks. This eliminates resending out your extrusions and heat sinks for a secondary process to separate multiple vendors. The significant advantage to this is our extrusions, and heat sinks customers now only have one source responsible for your quality and on-time delivery needs.

“Cradle to Grave” means as your extrusions and heat sinks mature, we will continually give you suggestions (process changes, material changes, sub-assemblies) to reduce your cost giving you an improved sales advantage. An example would be perhaps at the beginning of marketing your product, and your volumes are low. Since Ionthis is a component manufacture, we can produce low volumes. Typically extruders want customers to buy thousands of feet of the extruded bar even when the customer only needs 100 sets.

Ionthis is set up to meet the customer requirement on extrusions and heat sinks and will run only one or two Randoms with a lower cost; low volume dies to meet our customer’s smaller quantity requirements. When our customer volumes become high enough to justify a high production die or other processes to reduce the part cost, then Ionthis will recommend moving a high production mold or other processes to REDUCE COST. This is “Cradle to Grave.”

For a DFM/Analysis and recommendations of your Precision Extruded Components or Heat Sinks, feel free to contact Ionthis at engr@ionthis.com