Home » About

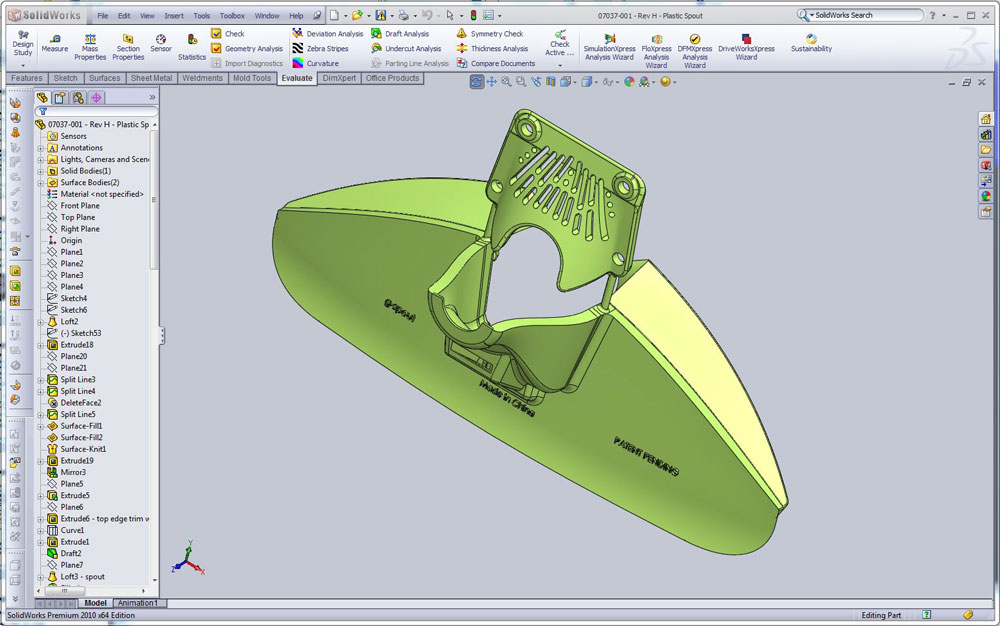

We are a FULL SERVICE “Cradle to Grave” Contact Manufacturer.

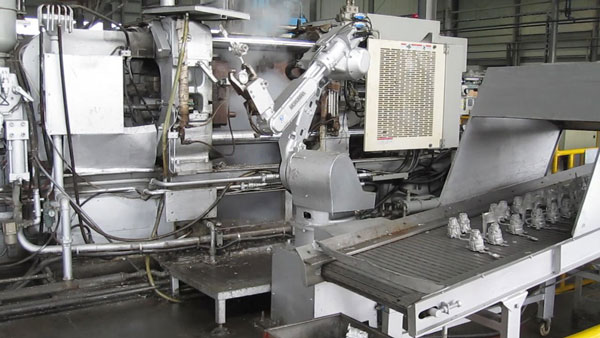

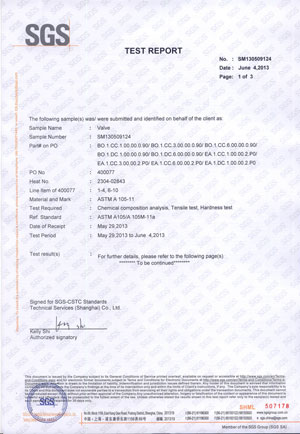

Ionthis’s value proposition is that we manage the manufacturing within an approved/audited factory, most factories of these factories we have done successful business with for years.

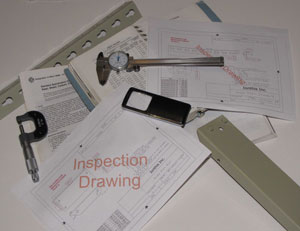

Our personnel manages all stages, from purchasing raw material through manufacturing, inspection, packing. We even control the shipping taking full responsibility for the product to meet and exceed our customer’s quality and design requirements. This is who we are.