Home » MFG Process Blog » What is Die Casting? An Overview of Its Benefits and Limitations

What is Die Casting? An Awesome Overview of Its Benefits and Limitations

Die casting is a manufacturing process that is used to create metal products. But it is not one that everyone’s as familiar with as they should be.

If you are wondering ‘what is die casting,’ we have got you covered.

Let us take a look at everything you need to know.

So, What Is Die Casting?

During the process, molten metal is injected at significantly high pressures into a mold to be formed into specific shapes in the molds.

Since it is relatively easy to manipulate the shape of metal substances that have reached temperatures this high, die casting is most commonly used in the industrial, lighting, communications, and automotive markets.

What Advantages Does It Have?

Die casting is one of the most effective methods for mass production. Since this saves manufacturing companies a significant amount of time and money, it also results in lower prices for consumers.

Additionally, companies can produce a much larger volume of metal products within a given period of time.

The products created through this method are also renowned for their dimensional accuracy. Since steel molding tools are used during die casting, each part is virtually guaranteed to be identical with high dimensional accuracy. Many parts are designed to be used “as cast.” As cast means a casting with no added secondary processes and minimal machining, just small items like tapping. In addition, die cast parts can be finished cosmetically “as cast” with an excellent appearance.

Die-casted products are also known for their strength, weight, heat resistance, and standards.

Metal components manufactured through die casting do not contain separate parts. Instead are a single part themselves due to the molding process. This attribute is where their strength is derived from.

Despite their impressive durability, when manufactured from materials such as aluminum, zinc, and magnesium, these products are also relatively light, making them far easier to transport, handle, have excellent thermal conductivity, and are easy to work with.

What are the Limitations?

Despite the advantages that die casting provides, it does come with a few limitations when you learn about what die casting is.

As you may expect, it is not cheap to produce this quality level on a large scale. Although companies can increase efficiency in the long run when it comes to creating quality parts, the early stages come with a hefty price tag.

NRE and Set-up Cost

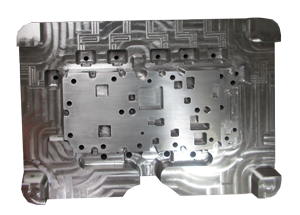

The initial cost is first with the die/mold. Mold cost is instead a complicated mold to allow injection of molten metal and to retain high dimensional accuracy.

Second is the set-up time and cost. The mold must be set up into the injection machine. Then it takes time to melt and test the molten metal for quality. Additionally, test runs and adjustments to the mold setup must be made.

For these reasons, small runs are not affordable from many factories.

Per Part Cost

Companies with large budgets for NRE will feel this less than smaller companies. If your manufacturing process only allows for small-scale die casting, it may be better to research another way to achieve your production goals. Other options like investment casting are a great alternative at a very low cost for NRE.

Once you consider the NRE and set up cost, the cost per part is very low compared to many other processes.

Materials

It’s also impossible to work with a multitude of types of metal or alloy. Depending on your end goal, if non-ferrous materials such as aluminum, zinc, and magnesium do not meet your requirements, this may require you to use a different manufacturing process like sand casting or investment casting.

Additional Considerations

To ensure that die-casted products are not porous, a special method for evacuating air from the product can be used along with proper flux additives. Complications can easily arise during this process and can render the entire component defective if something goes wrong without the correct procedures carefully planned ahead of time considering the injection machine’s size, material to be melted, simple or complex mold, and pressure used on the ram.

Understanding Die Casting Can Seem Difficult

But understanding what die casting is does not have to be.

With the above information about ‘what is die casting’ in mind, you will be well on your way toward understanding its utility and limitations.

Want to learn more about how we can help? Feel free to contact us today to see what we can do or read more about Die-Casting under our Manufacturing Process Explained.